Our

Services

Delivering Excellence in Control Systems

Expertise gained over many years in the industry means we deliver expert solutions in electrical control panels and systems.

We pride ourselves on precision, quality assurance, and client-focused service, providing custom-designed control systems that ensure seamless, safe, and efficient operations, with rapid response and open communication at every stage.

We Engineer

Our experienced design team creates comprehensive packages tailored to your specific needs.

These include detailed layout drawings, schematics, parts lists, cable schedules, and manuals. Using the latest AutoCAD software, spreadsheets, and word processors, we ensure precision and accuracy. We also specialise in ATEX design and the procurement of certified instrumentation, ensuring reliable performance for your required functions.

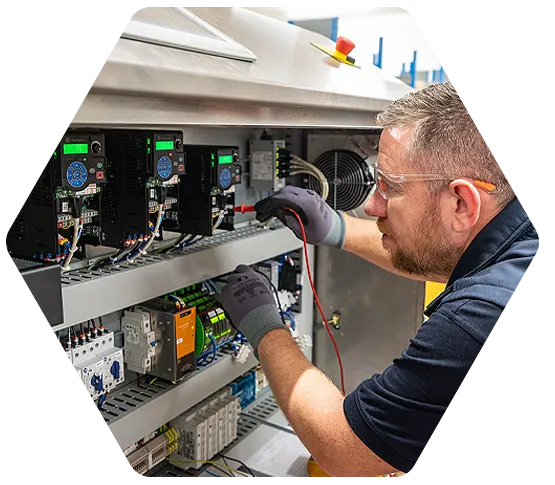

We Design & Build

Our workshop manufactures a wide range of Control Panels, from compact Control Stations to fully fault-rated Motor Control Centres and LV Switchboards. We use both standard and custom-designed cabinets and enclosures to meet your exact specifications.

All Control Panels are designed and built in compliance with BS5486 standards. Additionally, we offer an engraved label service to personalize your panels with your logo and service number.

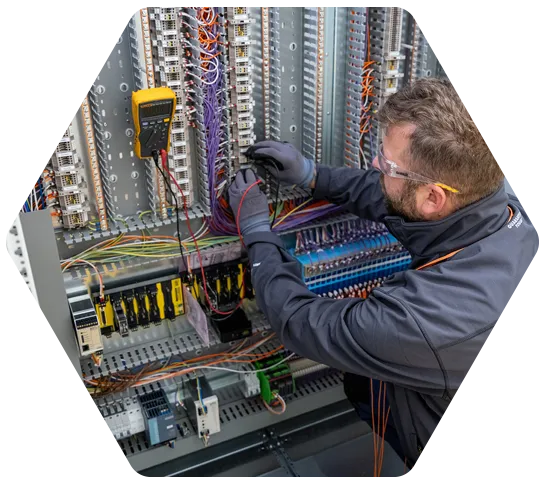

We Test

Control panels and PLC systems can undergo full I/O testing by connecting to our in-house simulation panels, reducing the need for costly on-site testing.

We also offer FAT simulation software, which can be executed in-house or remotely, allowing you to visualise how the system will operate through HMI displays before installation.

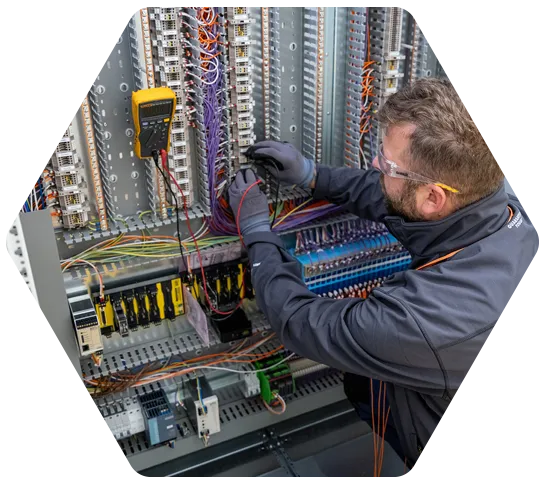

We Install and Commission

We handle all installations, from full distillery projects to production lines and process systems for the food and beverage industry.

Our engineers are fully versed in the latest IEE regulations and hold valid contractor safety group passports. Additionally, all our engineers are fully ATEX trained and COMPEX certified, ensuring the highest standards of safety and expertise.

We Calibrate

Tank calibration is fundamental for operational efficiency and regulatory compliance while giving operators confidence regarding the accuracy of their measurements.

Our state of the art, portable calibration rig with its UKAS calibrated Coriolis flowmeter can be moved to and around any site to provide the reliable and accurate measurements required by Customs and Excise. We can also provide calibrations certification and strapping tables for each tank.

WhO WE DO IT FOR

We work across all industry sectors but have particular specialist knowledge and experience of the challenges and particular requirements of these key industries:

Ready to get started?

Our team are ready to help with your next project. Get in touch to start the conversation.